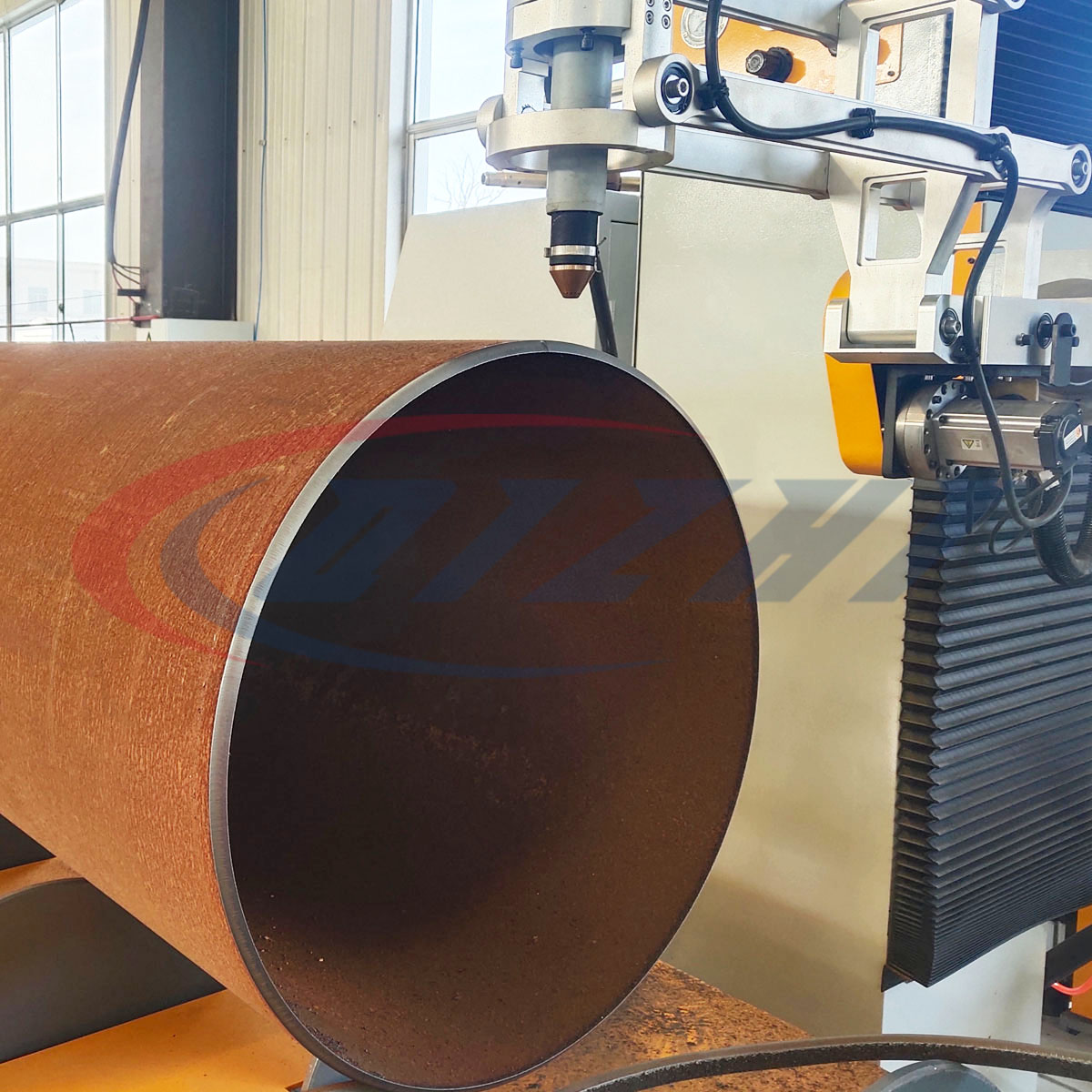

It is a specialized equipment for cutting, beveling, and profiling of steel pipes.

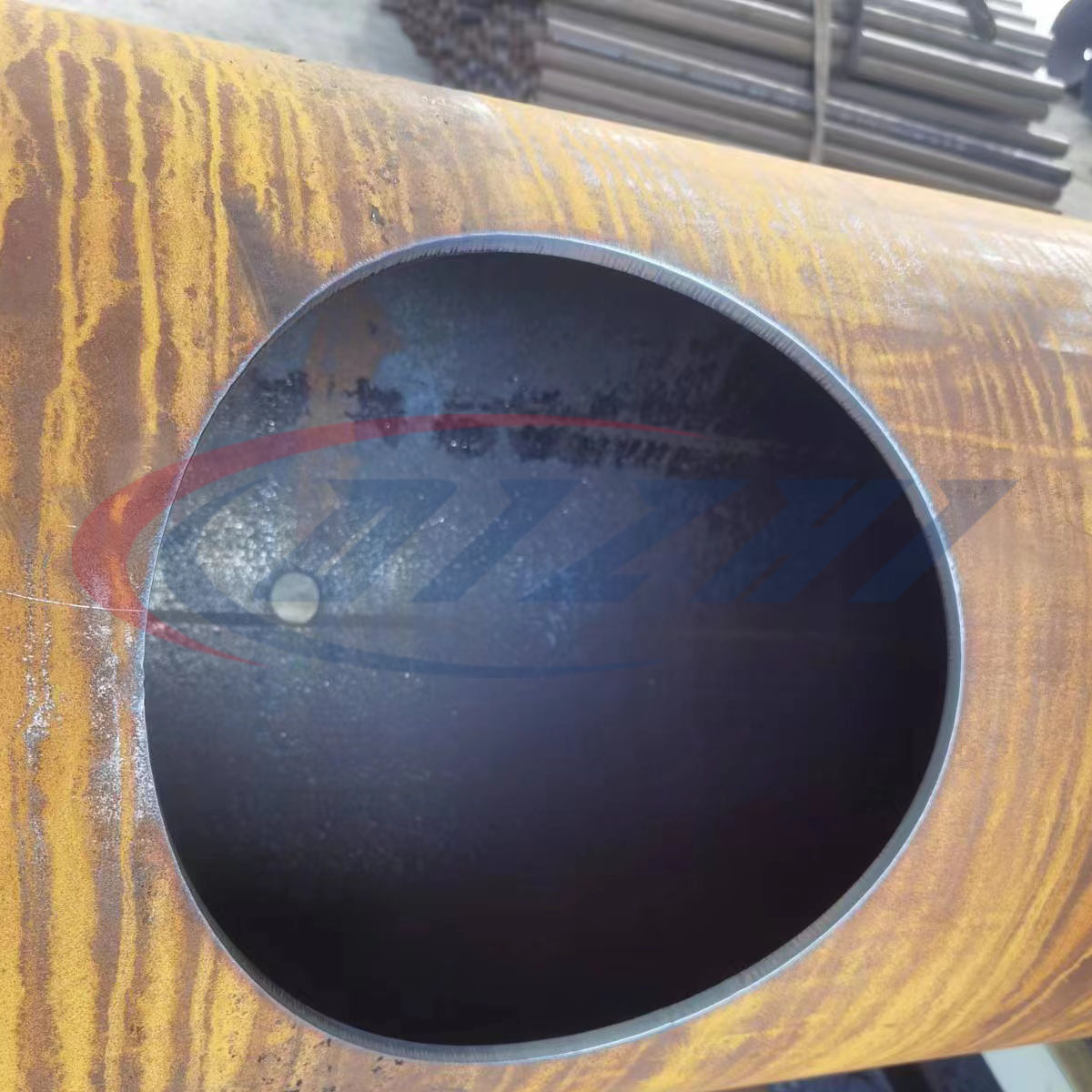

This machine is widely used for cutting and processing pipes in industries such as shipbuilding, construction, petrochemical, chemical, pipe towers, and steel structures.

In these industries, there are a large number of pipes cutting processing, groove processing, intersecting line holes, intersecting line ends and other processing, as well as commonly known “shrimp joints” elbows.

Most of these processing methods are outdated and complex, such as making templates, marking lines, manual layout, manual cutting, and manual polishing. The multi-axis plasma and flame automatic pipe cutting and profiling machine can automatically cut such workpieces.

The operator does not need to program, only needs to import cutting drawings or select cutting graphics from the industrial computer library, and then input parameters such as pipe radius and intersection angle that cooperate with each other. With just one click, the machine can automatically complete the cutting.