00:00

00:00

00:00

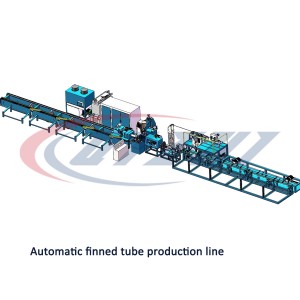

Features

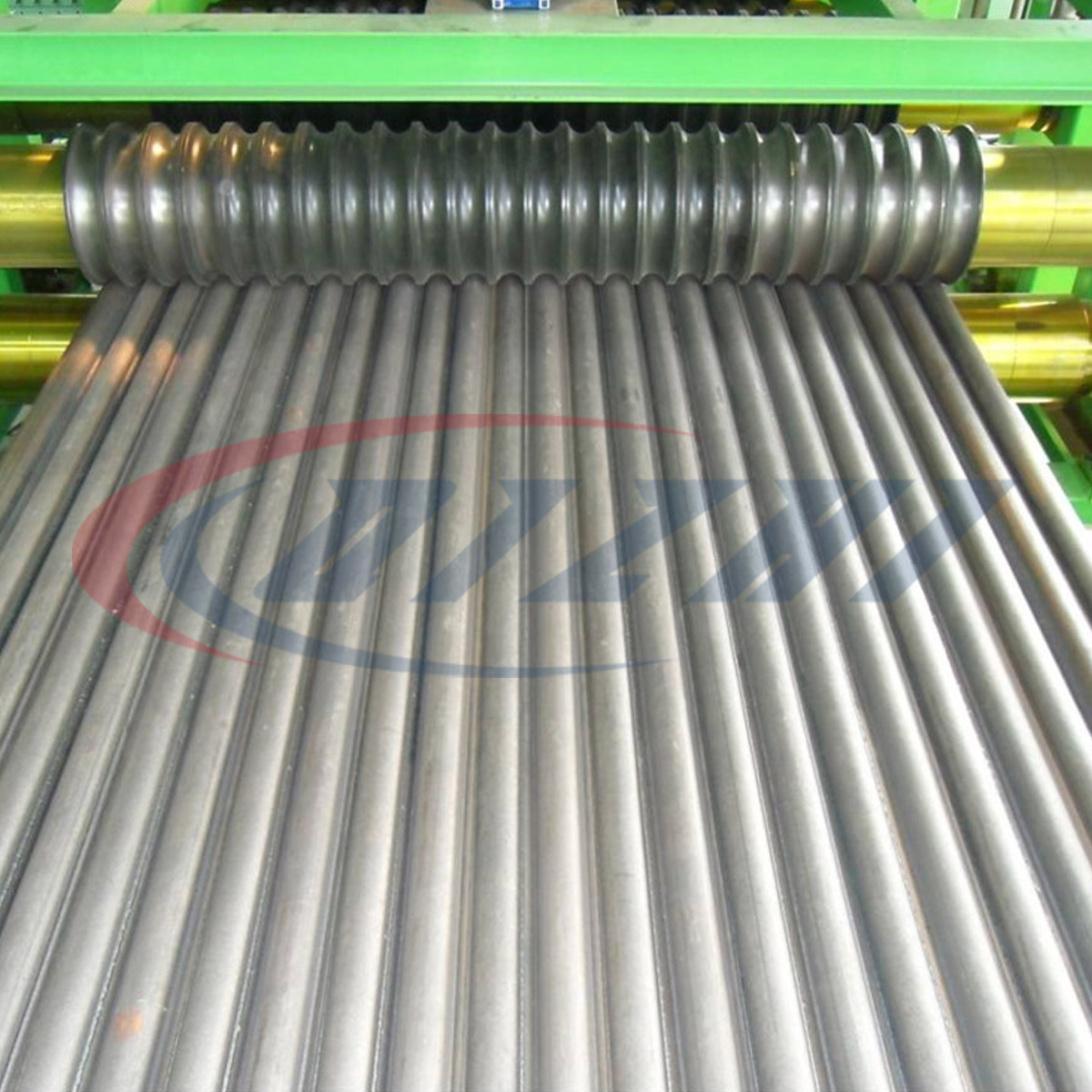

- provide streamlined logistic for tubes and flat steels;

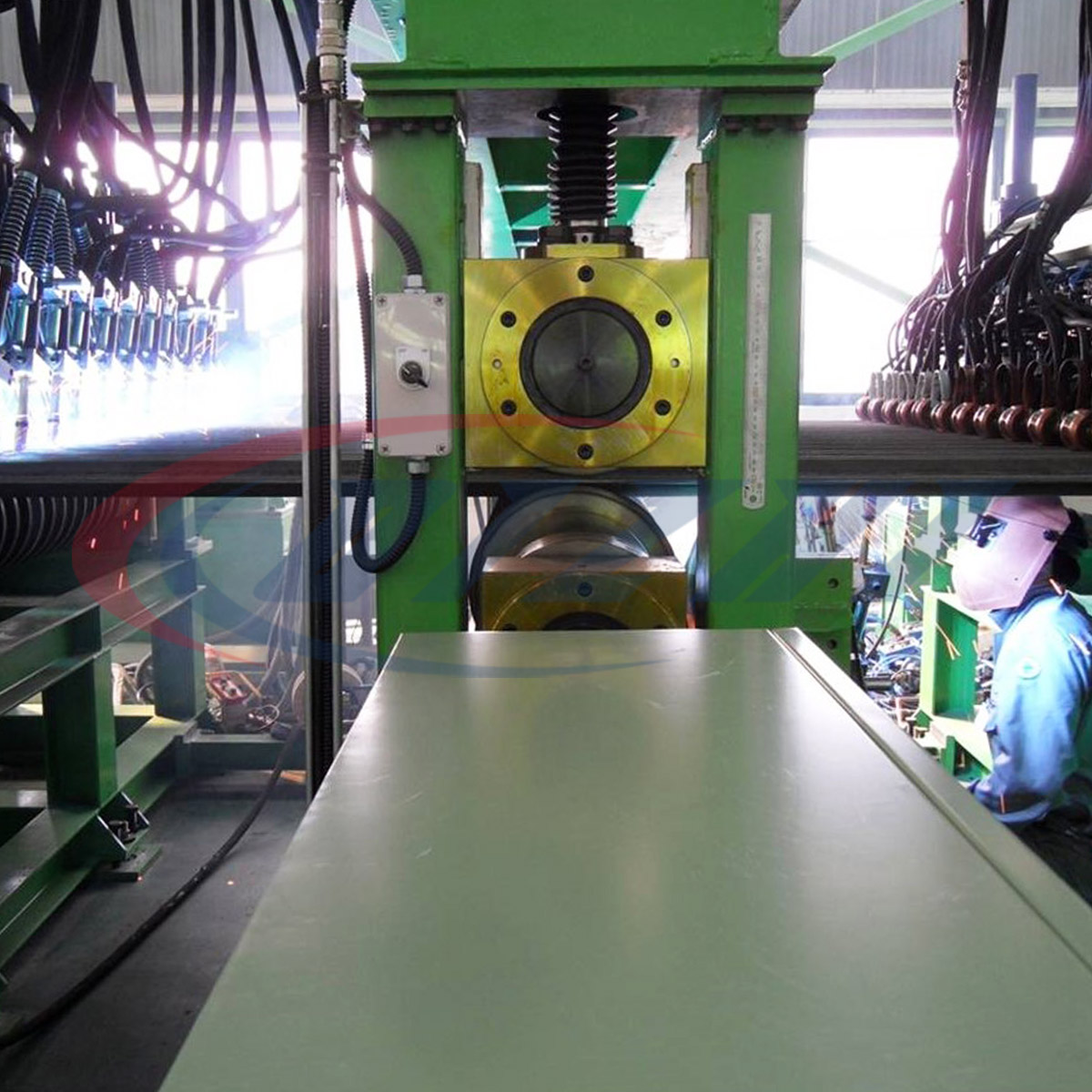

- specialized conductive mechanism (international famous brand) to direct current to each welding seam and improve anti-interface ability;

- improve the clamping force of the upper pressing roller to effectively ensure the clamping and closing force of the groove wheel on the panel during welding, as well as the stability of the center position of the flat steel;

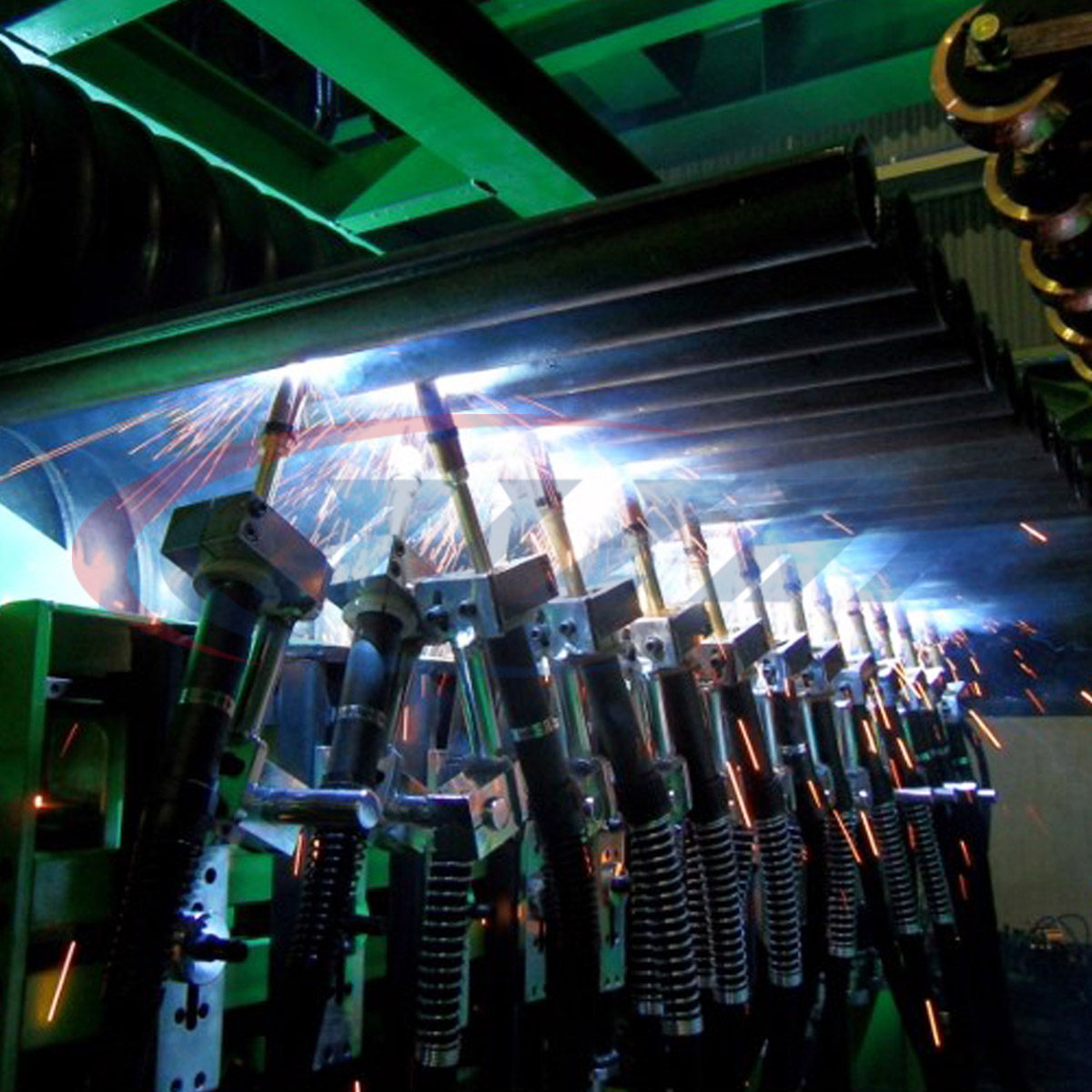

- more welding torches can be applied in the whole production line.

Specifications

Write your message here and send it to us